Decades ago, the consumer goods industry was represented by the local stores, malls, and sales representatives, but today’s industry stands pervasive and pertinent, empowered by the latest technological advanced infrastructure. As a result, the sales environment of fast-moving consumer goods (FMCG) is undergoing massive alterations, and the brands that are quick to embrace the latest technology and data to reach their audience and optimize consumer experience will succeed. Tracking consumer behavior, face recognition augmented reality, and algorithm analysis is now part of modern advanced life and can be widely used to customize items presented by FMCG organizations or retailers.

Digitalization has only picked up in the last few years and is still in the early stage of advancement in various FMCG organizations. Indeed, even notable brands are currently at an intersection of how they deal with the interface with the client. However, brands are certainly putting much effort into communicating digitally with their customers to gain insights and educate them simultaneously.

The New Shift in the Environment

Over and beyond 5-10 years, the FMCG sales environment has shifted considerably, bringing about an assortment of barriers for brands to work around.

The decreased shelf space in the brick-and-motor stores results from the stores conveying fewer lines. Food provision retailers have added non-food varieties and services to sustain growth and development. Furthermore, with the rapid emergence, consistent development, and progress of discounted retailers, the price has played the kingpin.

Concurrently, the cutting-edge consumer has grown more demanding than in history because of the diverse scope of choices on offer. However, digitalization offers extraordinary opportunities for progress – especially for smaller, deft brands that have the significant ability to adapt rapidly. The way to win more space on the store’s shelves and keep up with the competition is to zero down on creating customer interest beyond the boundaries of the store. That requires a completely integrated online and offline media stratagem, focusing on customer targeting and geolocation.

Brand awareness at large has become progressively significant in this packed, crowded market. It’s insufficient to have only one selling point of differentiation. Moreover, brands need a whole new bundle of attributes to optimize their appeal to their target audience.

Implement Digital Technologies

The first step to digitizing your supply chain is to implement digital technologies. This can include everything from cloud-based software to robotics and automation. By leveraging these technologies, businesses can improve the efficiency of their supply chains and reduce the risk of errors.

For example, implementing a cloud-based inventory management system can help businesses track inventory levels in real-time, ensuring that they always have the right amount of stock on hand. This can help prevent stockouts and overstocking, which can both be costly for businesses.

Similarly, implementing robotics and automation can help businesses streamline their supply chains and reduce the risk of errors. For example, using robots to handle repetitive tasks, such as picking and packing, can help reduce the risk of human error and improve overall efficiency.

Source: ESDS

Embrace Data Analytics

Another key component of a digital supply chain is data analytics. By collecting and analyzing data from across the supply chain, businesses can gain valuable insights into customer demand, supplier performance, and overall supply chain efficiency.

For example, by analyzing customer demand data, businesses can better anticipate changes in demand and adjust their inventory levels accordingly. This can help prevent stockouts and improve customer satisfaction.

Similarly, by analyzing supplier performance data, businesses can identify areas for improvement and work with suppliers to optimize their performance. This can help reduce lead times and improve overall supply chain efficiency.

Establish Strong Relationships with Suppliers

Digitizing your supply chain is not just about implementing new technologies and collecting data. It is also about establishing strong relationships with suppliers. By working closely with suppliers and fostering open communication, businesses can better understand supplier capabilities and build trust.

This can help reduce lead times, improve quality, and ensure that suppliers are able to meet demand. For example, by working closely with suppliers, businesses can develop contingency plans to address potential disruptions, such as natural disasters or supplier bankruptcies.

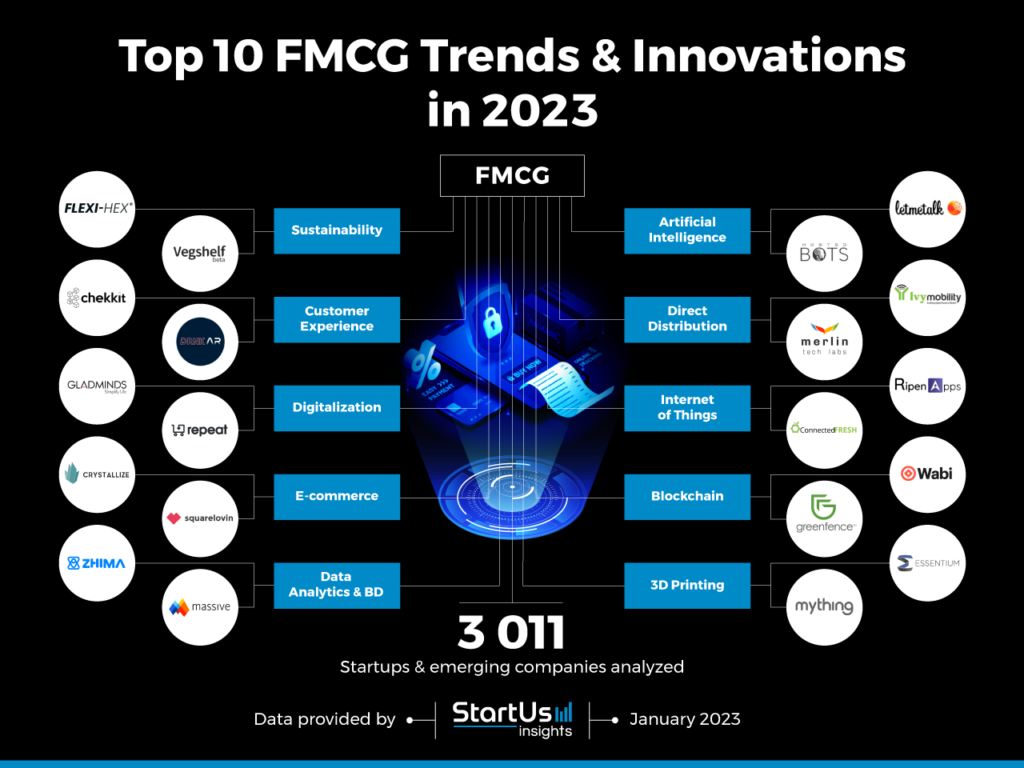

Source: StartUS

Emphasize Collaboration

Finally, to digitize your supply chain, you need to emphasize collaboration. This means breaking down silos and encouraging cross-functional collaboration across the supply chain. By bringing together stakeholders from across the organization, businesses can ensure that everyone is aligned around the same goals and objectives.

For example, by involving sales and marketing teams in supply chain planning, businesses can better anticipate changes in demand and adjust their supply chain accordingly. Similarly, by involving logistics teams in product development, businesses can ensure that products are designed with the supply chain in mind, reducing the risk of supply chain disruptions.

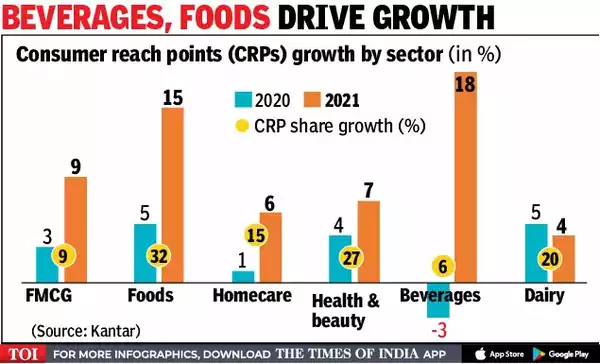

Source: TOI

How Riggle can help to Digitizing the General Trade supply chain for FMCG manufacturers

Riggle can be a valuable tool for FMCG manufacturers looking to digitize their general trade supply chains. Here are a few ways in which Riggle can help:

- Demand Forecasting: Riggle’s demand forecasting module can help FMCG manufacturers accurately predict demand for their products. By analyzing historical sales data, seasonality, and other factors, Riggle can generate accurate demand forecasts that can help manufacturers optimize their production schedules and inventory levels.

- Inventory Optimization: Riggle’s inventory optimization module can help FMCG manufacturers optimize their inventory levels. By providing real-time visibility into inventory levels at various stages of the supply chain, Riggle can help manufacturers avoid stockouts and overstocking, which can lead to lost sales and increased costs.

- Order Management: Riggle’s order management module can help FMCG manufacturers streamline their order management processes. By providing a single platform for order processing, tracking, and fulfillment, Riggle can help manufacturers reduce errors and improve order fulfillment rates.

- Route Optimization: Riggle’s route optimization module can help FMCG manufacturers optimize their distribution routes. By analyzing delivery locations, traffic patterns, and other factors, Riggle can help manufacturers optimize their delivery schedules and reduce transportation costs.

- Sales Analytics: Riggle’s sales analytics module can help FMCG manufacturers analyze sales data and identify trends and patterns. By providing real-time visibility into sales performance, Riggle can help manufacturers optimize their sales strategies and product portfolios.

Bottom Line

In conclusion, digitizing your supply chain is essential for meeting demand in today’s fast-paced business environment. By implementing digital technologies, embracing data analytics, establishing strong relationships with suppliers, and emphasizing collaboration, businesses can build resilient and efficient supply chains that can adapt to changing market conditions.